& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

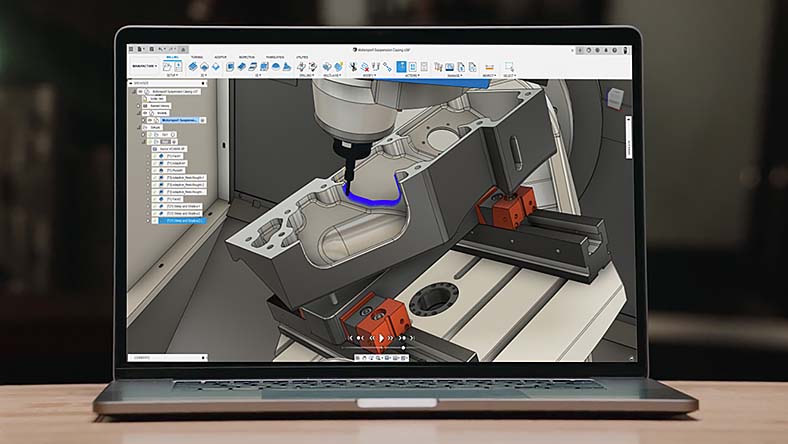

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Machining is a single stage within the manufacturing process that may encounter obstacles and challenges.

Autodesk Fusion is the first and only cloud product development platform on the market that seamlessly integrates design, engineering, and manufacturing workflows.

Eliminate the need for multiple tools and get rid of the headache of data translation issues. Start streamlining your workflows, optimizing designs for manufacture, and produce higher-quality, cost-effective parts.

Eliminate the need for back-and-forth file sharing or data lost in translation with a single CAD/CAM tool that can take you all the way from design to manufacture.

Create superior surfaces with proven machining strategies, advanced tool axis controls, and quality control processes

Increase your productivity through automation, collaboration, and interoperability to reduce non-value added processes.

Reduce costs and maximize resources by optimizing your processes with a single integrated manufacturing solution.

Integrations with leading OEMs help streamline common tasks. Learn more about Autodesk partnerships with industry leaders.

A fully integrated manufacturing workspace connects design and engineering to your manufacturing process.

Access a range of powerful 3-axis machining strategies to rapidly create high-quality NC code to rough and finish your 3D parts. Intuitive workflows make it simple to program individual features or entire parts.

Use specialized 4- and 5-axis toolpaths to achieve superior surface finish. Additional tool axis controls and automatic collision avoidance help you achieve safe, smooth and predictable machine motion.

Use CAD-based probing and spindle mounted probes to measure and improve the accuracy of your CNC machining. Intelligent part alignment helps save time and produce better quality parts

Combine milling and turning operations together to generate NC code that can help you produce more complex parts using multi-tasking hardware capable of supporting both styles of machining.

Access advanced tools for complex CNC machining, sheet nesting, and additive technologies to increase your manufacturing capabilities.

Increase in time to take a product to market with integrated CAD/CAM

Cut costs in half by reducing cycle times unnecessary hours spent on rework.

Create toolpaths twice as quickly and get to the machine faster.

1-year subscription: most popular, 1-year access to advanced CAD, CAM, CAE, PCB, data management, and collaboration tools with Autodesk Fusion.

1-year subscription: Combines core capabilities in Autodesk Fusion with professional-grade tools in the Manufacturing Extension for 3D printing, CNC machining, sheet-metal fabrication, and more.

Connect with a representative to discuss Autodesk Fusion and find the solution that best fits your company’s product development needs.

Extensions allow you to unlock advanced design and manufacturing technologies in Autodesk Fusion.

Want to try Autodesk Fusion? Download a free 30-day trial

Don’t settle for a siloed approach. See how an integrated CAD, CAM, CAE, and PCB software platform delivers unprecedented value to designers, engineers, and manufacturers.

This guide highlights important tools to be aware of, best practices, and things to be aware of as you get up to speed with the manufacture workspace.

Learn about the five sub-features of turning in Autodesk Fusion and how applying them can help your next project.

Unlock the power of automation in Autodesk Fusion CAM with these techniques to help improve productivity when machining your next part.

Learn how 5-axis machining works in Fusion — from 5-axis use cases to selecting a strategy and more.

Discover the benefits of 4-axis machining with Autodesk Fusion, including enhanced precision, reduced tool deflection, fewer setups, and more.

Learn how probing in Fusion saves you time and money and makes machine setup faster.

CNC machining, or Computer Numerical Control machining, is a manufacturing process that uses computer-controlled machines and tools to produce precision parts and components from various materials. It's a widely used manufacturing technique in industries such as aerospace, automotive, medical, electronics, and more.

CNC machining software refers to a category of computer programs and tools that are used in the CNC (Computer Numerical Control) machining process. CNC machining software is needed to design, program, and control CNC machines, which are used to manufacture precision parts and components.

CAD/CAM refers to the integration of Computer-aided design (CAD) and Computer-aided manufacturing (CAM). CAD/CAM software is used to design and manufacture prototypes, finished products, and production runs of products using a single development tool.

CAD/CAM (Computer-Aided Design and Computer-Aided Manufacturing) software is used for a wide range of applications in various industries. It plays a crucial role in the design, engineering, and manufacturing processes. Some common use cases include product design, mechanical and industrial design, automotive design, electronic circuit design, and medical device design.

CAD/CAM software plays an important role in modern design and manufacturing, offering numerous advantages, including increased innovation, efficiency, precision, cost reduction, and the ability to create complex and customized products.

While there isn't a one-size-fits-all all answer, Autodesk Fusion is a versatile CAD/CAM software that offers a wide range of design and manufacturing tools at an affordable price.

CAM stands for Computer-Aided Manufacturing. It is the use of CNC software to control machine tools and related machinery in the manufacturing of workpieces.

CNC stands for Computer Numerical Control. It is a manufacturing process in which pre-programmed CNC computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers.

CNC software is used for a variety of purposes in the manufacturing field for designing products, producing complex designs, rapid prototyping, machining parts, mass production and more.