& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

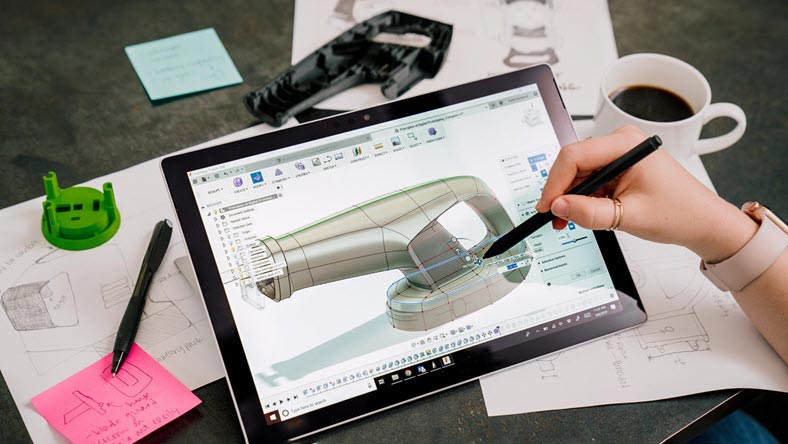

Professional CAD/CAM tools built on Inventor and AutoCAD

Fusion provides mechanical engineers with a unified platform to seamlessly bridge the gap from concept to manufacture. CAD, CAM, ECAD, and simulation all in one place eliminates the need for multiple tools and allows teams to collaborate and connect in real-time, regardless of location.

Advanced simulation capabilities allow for the validation of designs, while integrated CAD/CAM guarantees a smooth transition from design to production. ECAD brings electronics design into the fold, enabling true interdisciplinary projects. With its cloud-centric system, all design data remains synchronized and secure.

Create 3D models, engineer, simulate, and manufacture all-in-one product development solution.

Solve engineering challenges faster, with flexible 3D modeling, simulation, and generative design tools.

Eliminate the need for back-and-forth file sharing across multiple tools by standardizing on a single CAD, CAM, CAE, PCB, data management, and collaboration software soution.

Create history-based features, including extrude, revolve, loft and sweep that update with design changes.

Assemble designs with a traditional bottom-up, middle-out, or top-down approach, and analyze assembly motion.

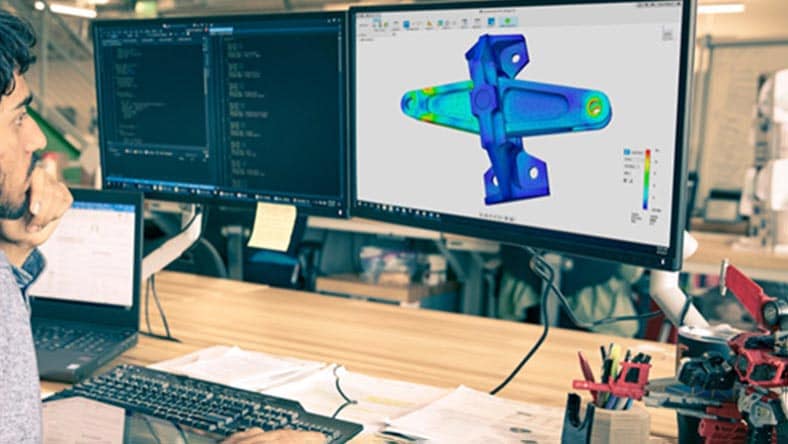

Test your designs to make sure they will survive real-world conditions. Simulate your products digitally, reducing the cost of prototyping by using fully validated solvers.

Remove silos from your traditional design process and use a modern collaboration environment. Connect teams and stakeholders, communicate in real-time, and centralize project activity.

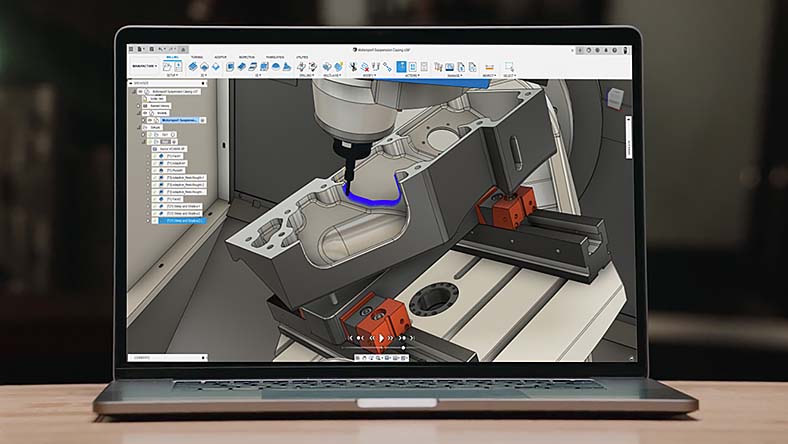

Produce high-quality CNC machined parts, and additively manufacture builds using FFF or BPF for metal 3D printing.

Make sure that your PCB fits the first time, every time with the only truly unified MCAD to ECAD software solution.

Investigate upwards of 100 3D design iterations in the amount of time it would traditionally take to complete a single one.

Design, engineer, and manufacture a product in 1 day instead of a week.

Reduce your mechanical engineering time by 75% when compared to traditional 3D design methods.

Source: Lifecycle insights report

Don’t settle for a siloed approach. See how an integrated CAD, CAM, CAE, and PCB software platform delivers unprecedented value to designers, engineers, and manufacturers.

Autodesk Fusion is a game-changer for mechatronics, seamlessly integrating mechanical and electrical engineering. Design aspects that directly impact each other are easier when they're designed simultaneously in Fusion.

Explore the benefits of DFM (design for manufacturing) and discover which Autodesk Fusion features support the process.

Autodesk Fusion offers a unified, streamlined, and highly collaborative product development environment—from prototype to final product.

10 ways Fusion supports designers and engineers during the prototyping and fabrication stages of product development.

Explore how design automation tools like parametric modeling, generative design, and automated modeling in Fusion enable your team to grow smarter.

Fusion is the sum of its multiple, powerful parts. We’ll expand upon CAD, CAM, and CAE, advantages across crucial touchpoints in the end-to-end product development process.

Gain access to an assortment of simulation capabilities, including thermal simulation, structural simulation, generative design, and injection molding manufacturability with the Fusion Simulation Extension.

1-year subscription: most popular, 1-year access to advanced CAD, CAM, CAE, PCB, data management, and collaboration tools with Autodesk Fusion.

1-year subscription: Optimize part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection molding, and more. Requires a Fusion subscription.

Connect with a representative to discuss Autodesk Fusion and find the solution that best fits your company’s product development needs.

Extensions allow you to unlock advanced design and manufacturing technologies in Autodesk Fusion.

Want to try Autodesk Fusion? Download a free 30-day trial

CAD (Computer-Aided Design) software is a key tool utilized in mechanical engineering. It allows engineers to create precise 3D models, conduct simulations and analyses, and even control manufacturing processes. Autodesk Fusion is a leading example of a comprehensive CAD software platform.

CAM (Computer-Aided Manufacturing) software is critical to modern mechanical engineering. It translates CAD models into machine-readable instructions, streamlining the manufacturing process. Fusion's integrated CAD/CAM capabilities make it a powerful tool for mechanical engineers.

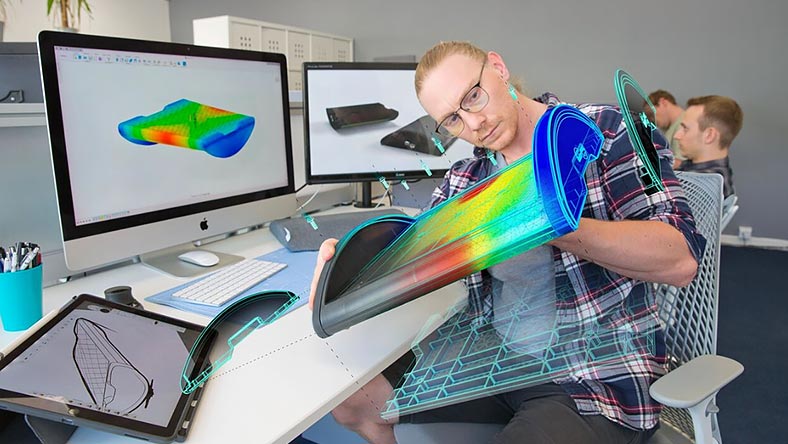

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that uses algorithms and numerical methods to solve and analyze problems involving fluid flows. In mechanical engineering, CFD software can simulate the performance of products subjected to fluid flows.

Computer-Aided Engineering (CAE) is a broad term encompassing several technologies, including CAD, CAM, CFD, and Finite Element Analysis (FEA). CAE tools are used in mechanical engineering to simulate, validate, and optimize products and manufacturing processes.

Mechanical engineering has several sub-disciplines, including automotive, aerospace, energy systems, and mechatronics. Fusion's versatile toolsets, which includes CAD, CAM, and CAE capabilities, caters to the diverse needs of these fields.

Autodesk Fusion provides an integrated platform for design, simulation, and manufacturing. Its broad range of tools allows mechanical engineers to conduct comprehensive design and analysis tasks, from creating 3D models to simulating real-world performance.