& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Concrete design refers to the process of planning, analyzing, and structurally designing structures or elements made primarily of concrete, a versatile and widely used construction material.

Image courtesy of Gate Precast

Reinforced concrete design is a specialized discipline within concrete engineering that involves enhancing the strength and durability of concrete elements by strategically incorporating reinforcement materials like steel bars or mesh. Engineers analyze structural requirements, choose suitable concrete mixes and reinforcement materials, adhere to building codes, and meticulously plan reinforcement elements to create robust structures capable of withstanding various loads and environmental factors. This approach is widely employed in construction projects, offering strength, versatility, and longevity; it has become a fundamental practice for designing safe and enduring buildings, bridges, and infrastructure.

Concrete stands out as a commonly used construction material due to its exceptional strength, durability, versatility, and cost-effectiveness. It is renowned for its ability to withstand heavy loads, weather conditions, and time while offering fire resistance and adaptability for innovative design solutions. Concrete’s sustainability, thermal mass, sound insulation, and resistance to moisture contribute to its appeal. Concrete boasts utilitarian performance features, as well as cost-effectiveness and aesthetic potential, making it a mainstay in construction projects, from buildings to infrastructure, worldwide.

Concrete design software plays a crucial role in building information modeling (BIM) processes by integrating with BIM platforms, providing accurate 3D modeling and structural analysis capabilities, ensuring code compliance, optimizing designs, offering visual representations for enhanced communication, generating comprehensive documentation, facilitating collaboration among project stakeholders, enabling conflict detection, and supporting sustainability assessments. This integration streamlines design coordination, data sharing, and decision-making within the BIM environment, contributing to more efficient and well-informed construction projects.

Modern technology revolutionizes concrete structure design by offering tools like CAD software for precise modeling, structural analysis software for performance optimization, BIM for integrated coordination, 3D printing for customized elements, and simulations to predict behavior. Remote sensing and material testing technologies enhance site selection and quality control while augmented reality (AR) and virtual reality (VR) enable immersive visualization. Sustainability and green building tools promote eco-friendly designs, and cloud collaboration platforms foster teamwork. Cost estimation, project management software, and robotics improve efficiency and precision, ultimately leading to safer, more sustainable, and innovative concrete structures.

Concrete design software offers many benefits to engineers, architects, and construction professionals involved in the design and analysis of concrete structures, including:

Concrete design software automates complex calculations and design processes, reducing the time and effort required for manual calculations.

Concrete design software allows engineers to explore multiple design options and quickly assess their impact on structural performance.

The software is typically designed to adhere to local building codes and international standards, ensuring that designs are compliant with regulatory requirements.

The software can perform clash-detection analyses by comparing the 3D rebar models with other structural elements within the same BIM environment.

Many concrete design software platforms are cloud-based, enabling real-time collaboration among team members, regardless of their physical location.

Powerful BIM and CAD tools for designers, engineers, and contractors, including Revit, AutoCAD, Civil 3D, Autodesk Forma, and more

BIM 360 is a construction management platform that connects, organizes, and optimizes projects from design to construction.

2D and 3D CAD tools, with enhanced insights, AI-automations, and collaboration features. Subscription includes AutoCAD on desktop, web, mobile, and seven specialized toolsets.

Gate Precast

Concrete precast company uses 3D-printed concrete molds to bring an ambitious building facade to life.

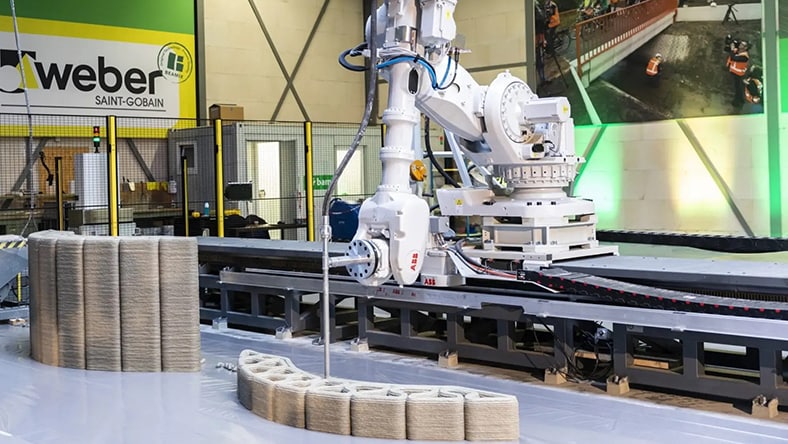

BAM & Saint-Gobain

Leading manufacturers save time and labor with sustainable, scalable, and affordable 3D concrete printing solutions.

Gate Precast

Architecture firm and concrete precast company collaborate with Revit to realize an innovative museum design.

Learn about the benefits of using BIM-centric solutions for reinforced-concrete construction projects.

See how the Hone Structures project pioneers a new approach to forming sustainable concrete.

See how Concrete Collective takes a digital approach to molds and nesting with Fusion 360.

In reinforced-concrete design, the Working Stress Method (WSM) assesses the safety of structures by comparing calculated stresses within concrete and steel to allowable limits, assuming elastic behavior within certain bounds. The Ultimate Strength Method (also known as Load and Resistance Factor Design, or LRFD) considers applied loads and the resistance capacity of materials such as concrete and steel to ensure safe designs. The Limit State Method (LSM) focuses on two key limit states: serviceability and ultimate strength, ensuring that structures remain functional, durable, and safe under all expected loads and conditions.

Concrete mixtures come in various types to meet specific construction needs. Normal-strength concrete (NSC) is standard for most projects while high-strength concrete (HSC) offers increased strength. Ultra-high-performance concrete (UHPC) excels in strength and durability. Self-consolidating concrete (SCC) flows without vibration, and fiber-reinforced concrete (FRC) resists cracking. Lightweight concrete is low density; high-density concrete is heavy. Shotcrete is pneumatically applied; pervious concrete is porous for drainage; and roller-compacted concrete (RCC) suits pavements. Shrinkage-compensating concrete minimizes cracks; colored concrete provides aesthetic options; and specialty mixes such as shrinkage-compensating and colored concrete cater to specific project needs.

Common concrete mix design requirements include the desired strength, durability, workability, and exposure conditions. Engineers must factor in the properties of aggregates, the type and content of cement, the water-cement ratio, and the inclusion of chemical admixtures to achieve the desired concrete properties. Proportions of these components are optimized to meet project specifications while ensuring cost-effectiveness and maintaining workability. Quality control measures, including material testing and trial mixes, are integral to ensuring the mix meets project requirements.