& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

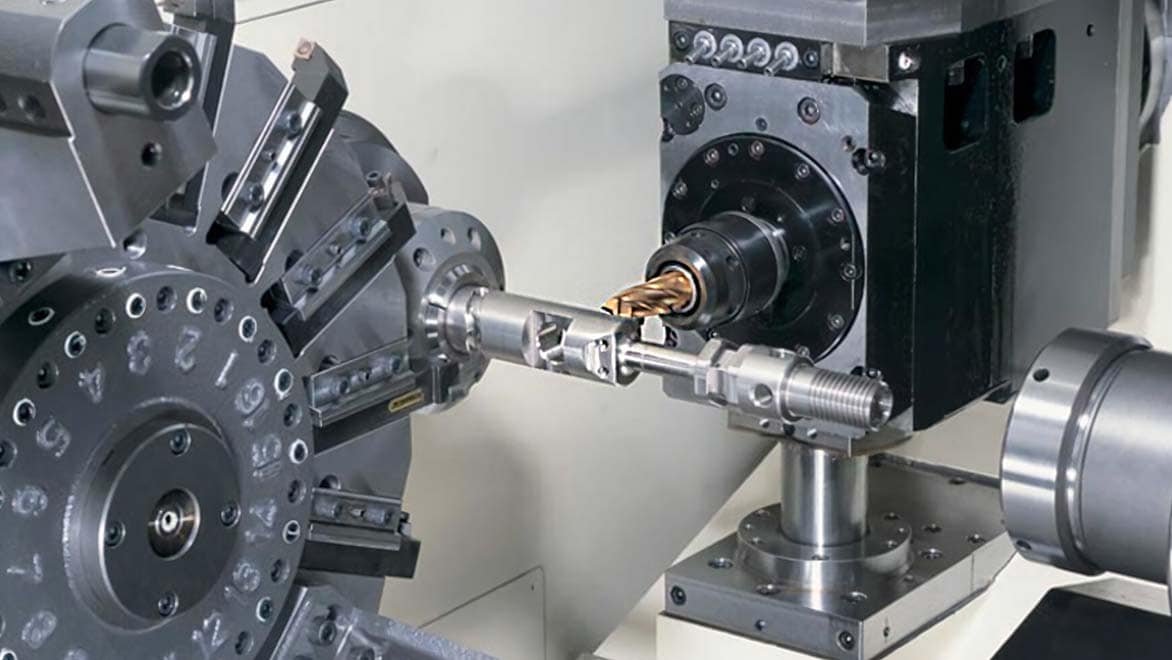

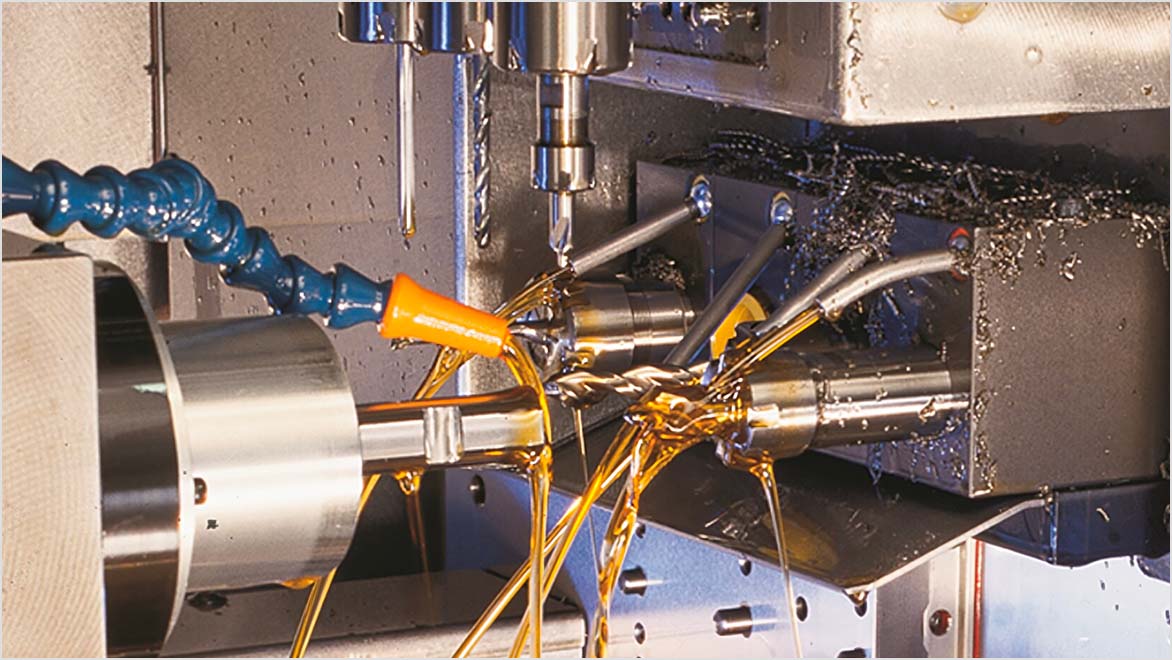

Swiss machining software allows you to program your multi-axis and sliding headstock Swiss lathes easily. Swiss CAM software such as Autodesk PartMaker® (included in Fusion 360 with FeatureCAM) can produce CNC programs that drive main and sub-spindle machining operations. These can be used for turning, indexed and interpolated C-axis milling, Y-axis, and B-axis milling.

Swiss machining software helps you quickly produce small, accurate parts through synchronous cutting on Swiss and multi-axis lathes. Visual synchronization in Autodesk PartMaker allows NC code to be created and optimized to maximize machine productivity.

Post processors allow CNC code to be exported to suit the unique capabilities of your specific machine tool. Autodesk PartMaker includes a library of proven, configurable post processors for Swiss and multi-axis lathes. Customize the NC output to suit your application with easy to use post processor edits.

Verify and visualize your Swiss machining process with a digital twin of your specific lathe. Autodesk PartMaker includes machine simulation and collision checking of Swiss and multi-axis lathes from major machine manufacturers, including twin-spindle multi-toolpost machines.

Fusion 360 with FeatureCAM software includes PartMaker for specialist CAM programming of Swiss and multi-axis lathes.

Gain focused Swiss strategies for precision machining.

Help increase productivity by reducing cycle times.

Program a wide range of Swiss and multi-axis lathes.

Simplify the production of multi-channel machining code.

ASTRO MEDICAL

This medical device manufacturer uses PartMaker to produce highly engineered precision parts for the medical industry.

Image courtesy of Astro Medical

MARVER MED

Production turning software enables this precision manufacturer to grow business and differentiate with more complex jobs.

Image courtesy of Marver Med

SMITH BROTHERS PUSHRODS

This manufacturer of superior-quality pushrods creates high-tolerance parts with minimal turnaround time.

Image courtesy of Smith Brothers Pushrods